-

WhatsApp

-

Email

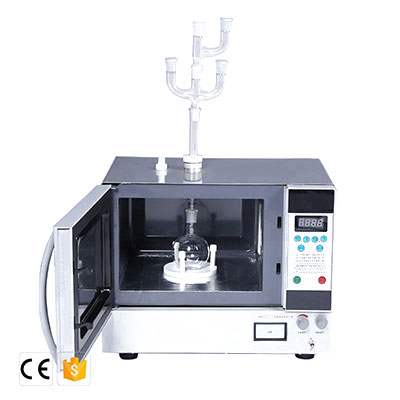

The industrial microwave chemical reactor can be used for continuous microwave heating. Pulse-free ultrasonic microwave is continuous output and pulse-free stimulation to achieve the purpose of continuous heating.

Microwave Chemical Reactor WBFY-205, Reliable shielding effectively eliminates any electromagnetic interference and self-heating effects.

Features

- Continuous microwave heating: Research shows that pulsed microwaves can generate high-threshold electromagnetic pulses when turned on and off, and the phenomenon of large temperature oscillations can easily destroy the morphology of organic molecules, thereby affecting experimental results.The characteristics of pulseless microwave continuous heating are: variable frequency microwave power adjustment, microwave output is continuous output, and no pulse stimulation.

- Strategy wave power variable frequency control: CPU technology is used to assist monitoring and control. Adaptive PID adjustment technology can overcome the occurrence of overshoot under the conditions of mathematical models such as ambient temperature changes, reaction material polarity, and heat capacity changes. Make the microwave adjust the microwave transmission power with the feedback of temperature, so as to accurately reach the temperature set value. Automatically adjust the power and the intensity of the reaction to achieve the desired control effect.

- Platinum resistance temperature control system: The shielded platinum resistance is directly inserted into the reactor, and the internal temperature of the reaction is measured, according to accuracy. Reliable shielding effectively eliminates any electromagnetic interference and self-heating effects.

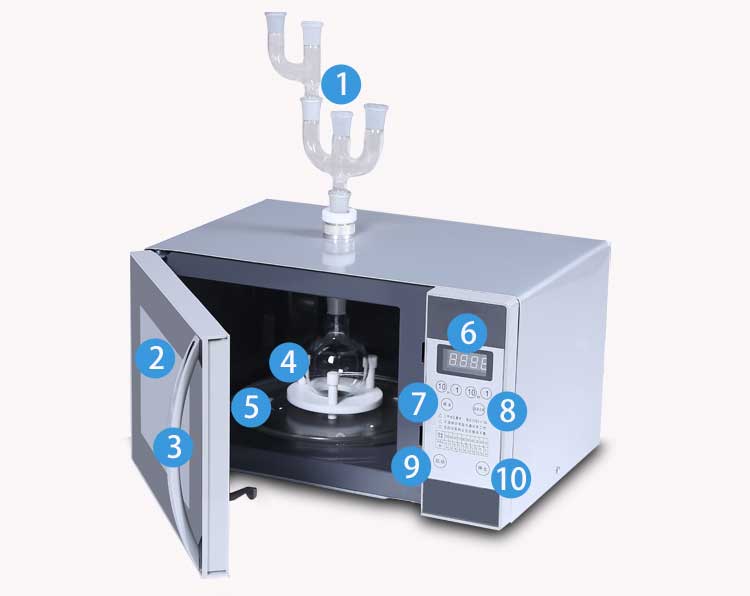

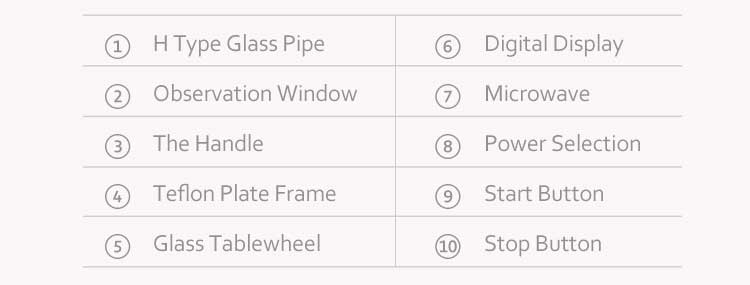

- Microwave power ten-step adjustment: We divide the power into ten steps within the microwave effective power range. The microwave power can be automatically controlled by variable frequency within the limited power range of each step, thereby limiting the severity of the reaction and the reaction speed.

- Five-step heating program: The temperature rising process of the reaction can be divided into five stages through the control of a microcomputer. The user can edit the reaction parameters: reaction temperature, reaction time, and maximum power. The microwave can also modify the reaction conditions without stopping the machine.

- Using a large-area touch panel: The buttons are distributed in accordance with the operating habits, the distribution distance is reasonable, and the operation feels more comfortable. And there is a sound prompt function.

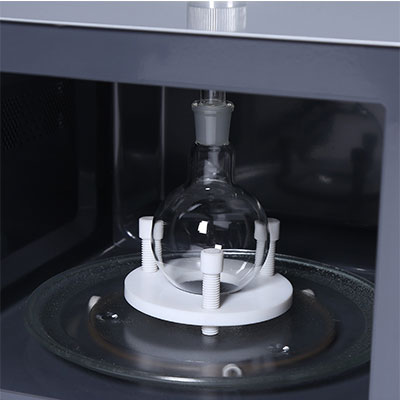

Detail

Use of microwave chemical reactor:

Chemical Microwave Reactors apply microcomputer technology and unique technology of microwave adjustment, realizing microwave power continuously adjustable, good repeatability. For experiments that require microwave assisted catalytic reaction conditions, especially for those who require a smaller microwave power and who wish to maintain continuous microwave radiation chemistry experiments, its scientificity and practicability are ideal to play.

After sale

- 1 year warranty service and all life maintenance.

- Technical Egineer are avalible for oversea trainning.

- Free change for some parts

- Remote control technical consult

- Free installation DVD

- Maintenance plan

Package

Transport

1. What should I pay attention to when using a microwave chemical reactor?

-The structure of the microwave reactor system is tight. Do not place heavy objects on the equipment door during use.The door gap is usually cleaned with a damp cloth. If there is damage or the microwave reactor is hit or squeezed, which deforms or damages the equipment or the casing, it must be stopped immediately to prevent microwave leakage.-Do not use closed containers without safety devices to react in a microwave oven to avoid an explosion.

-When the equipment is empty, do not operate inside the equipment, otherwise the safety device in the reactor will stop the system operation, and the furnace can be restarted after it has cooled down.

-Do not place any metal objects in the furnace, including metal containers.

2. Working principle of industrial microwave chemical reactor.

Microwave is a kind of high-frequency electromagnetic wave, which does not generate heat by itself. Microwaves in nature cannot be used as an energy source because they are not concentrated. The magnetron used can convert electric energy into microwaves and penetrate the medium at an oscillation frequency of 2450 MHz per second. When dissipated, high-frequency oscillations occur in the alternating electromagnetic field, causing energy to be accumulated in the medium.For chemical reactions, both thermal and non-thermal effects can occur.3. How to maintain the microwave ultrasonic reactor?

-Be sure to unplug the power plug before cleaning the microwave oven.-Wipe the microwave oven shell with a cloth moistened with a soft detergent (such as detergent), and wipe it with a slightly damp cloth, and then dry it with a dry cloth. Do not let moisture penetrate the oven cavity. Do not use hard objects such as wire brushes to wipe the microwave oven.

-Do not use poor cleaning agents and corrosive, volatile chemical solvents to wipe the furnace body to avoid damage to the furnace body.

-The dirt inside the chemical reactor must be cleaned frequently to avoid affecting the heating effect.

-The bottom of the device must be kept clean to avoid noise when the turntable rotates.

-Keep the waveguide opening in the device clean. Do not remove the waveguide cover (mica sheet) to avoid fire.

-Unplug the power plug when not using the microwave oven.

-Because the microwave chemical reactor has a large working current, please use a professional socket. Do not share a socket with other electrical appliances (especially air conditioners, heaters, etc.), which may cause short circuit overload and fire.