-

WhatsApp

-

Email

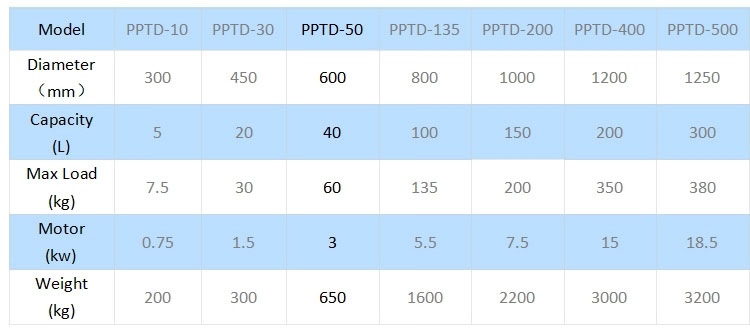

The basket centrifuge is made of stainless steel and has good corrosion resistance. The maximum capacity is 300L. Since the basket stainless steel centrifuge conforms to the GMP technical specifications and belongs to the GMP centrifuge, this centrifuge can be used in the cannabis separation process.

Features

-High-quality stainless steel liner, beautiful and solid appearance, long service life.

-Large capacity, high dehydration rate and low energy consumption.

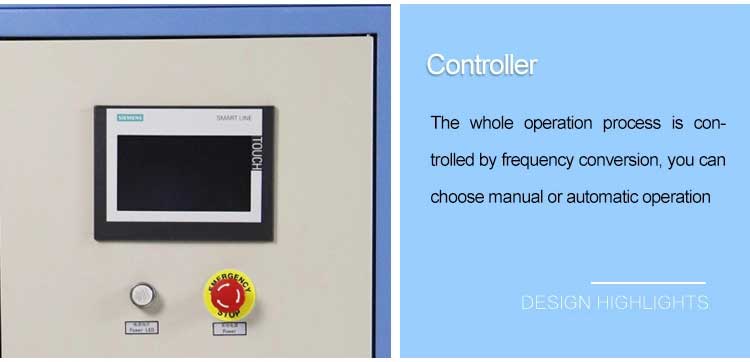

-The system adopts advanced and reliable frequency conversion control, which can automatically time, automatic braking, and speed can be selected and set as required.

-Cover switch protection device to ensure operation safety and body life.

-Full-automatic frequency conversion control, free of mechanical brakes, greatly reducing the rate of mechanical maintenance.

-Super quiet and super balanced, creating a first-class working environment.

Detail

Working principle and role of large centrifuge:

After sale

Package

Transport

1. What is the composition of the centrifuge?

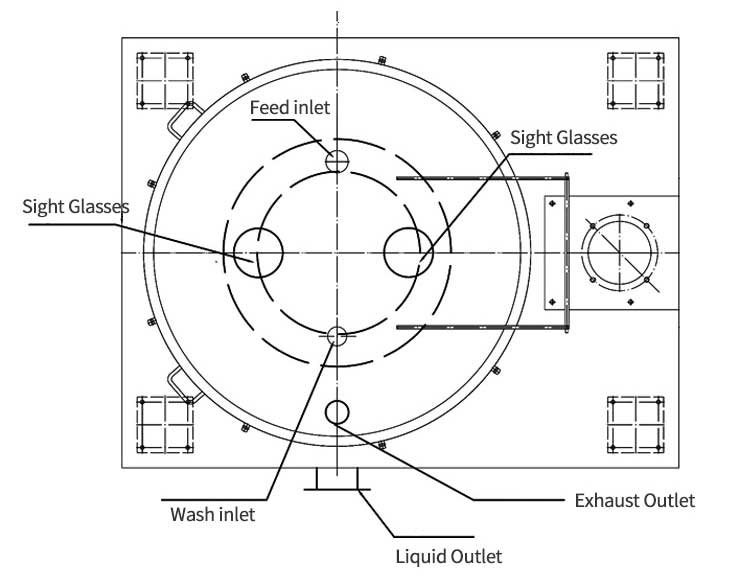

Centrifuge body parts include base, housing, locking mechanism, etc.Centrifuge cover parts include feeding tube, washing tube, nitrogen tube and other components.

2. What are the requirements of a GMP-compliant centrifuge?

- Containment requirements:

- Sealing of the cover.

- Sealing of bearing positions.

- Sealing of the drive belt working area.

- Sealing of interface parts such as liquid discharge pipe, feed pipe, discharge hopper, etc.

- Online cleaning requirements:

- A cleaning device is set in the inner cavity of the centrifuge, and the centrifuge can clean the invisible surface inside the centrifuge without opening the cover or during operation.

3. What should I pay attention to when choosing a centrifuge?

- Anti-corrosion performance:

- If the material separated by the stainless steel centrifuge is corrosive, the material in contact with the material must be able to meet the requirements of corrosion resistance to ensure safe use.

- Explosion-proof performance:

- If the material processed by the centrifuge (or the environment) contains flammable and explosive substances such as organic solvents, the centrifuge should have explosion-proof performance. The explosion-proof performance is determined by the explosion-proof requirements (grades) of the process.

- Separation performance:

- The separation performance of the basket centrifuge is a basic function, including the effect of separation, washing effect, processing capacity, degree of automation, etc. At the beginning of an order, it is difficult to determine the effect of the separation due to the differences in the properties of the materials, including the viscosity, particle size, density, and solid-liquid ratio of the slurry. Generally, the centrifuge's separation factor is used to measure the centrifuge seperate effect.